while production is ongoing,

or greenfield planning, supervision and start-up

we have experienced staff.

|

For the integration of new equipment with existing equipment while production is ongoing, or greenfield planning, supervision and start-up we have experienced staff. |

||

|

Consulting Engineers for Global Beverage Clients as Well as Local Customers |

||

| Our Expertise | |

|

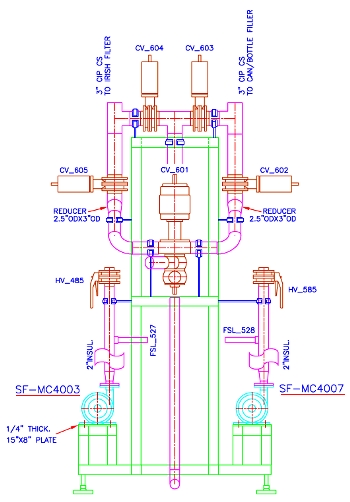

Develop Process Flow Models and simulations for sizing and cross-checking Analyze and Develop Detailed Piping and Instrumentation Diagram Develop Plant Capacity Planning Models Facility Upgrade Studies Support Purchasing with specific Equipment lists Detailed and Accurate Piping Drawings using 3 dimensional drawing software Functional Descriptions for Automation Purposes Design, Deliver and Start-up Custom Process Skids Communicate Preferably using Graphics Analyze Weak-Points, Bottle Necks and Propose Remedies We help our customers to design and / or source any equipment needed: from valves to fermentation tanks; from pumps to complete CIP stations; from separate pieces to skidded process systems; from sketch to start-up; from manually operated piping systems with jumper panels to fully automatic systems using mix-proof valves. |